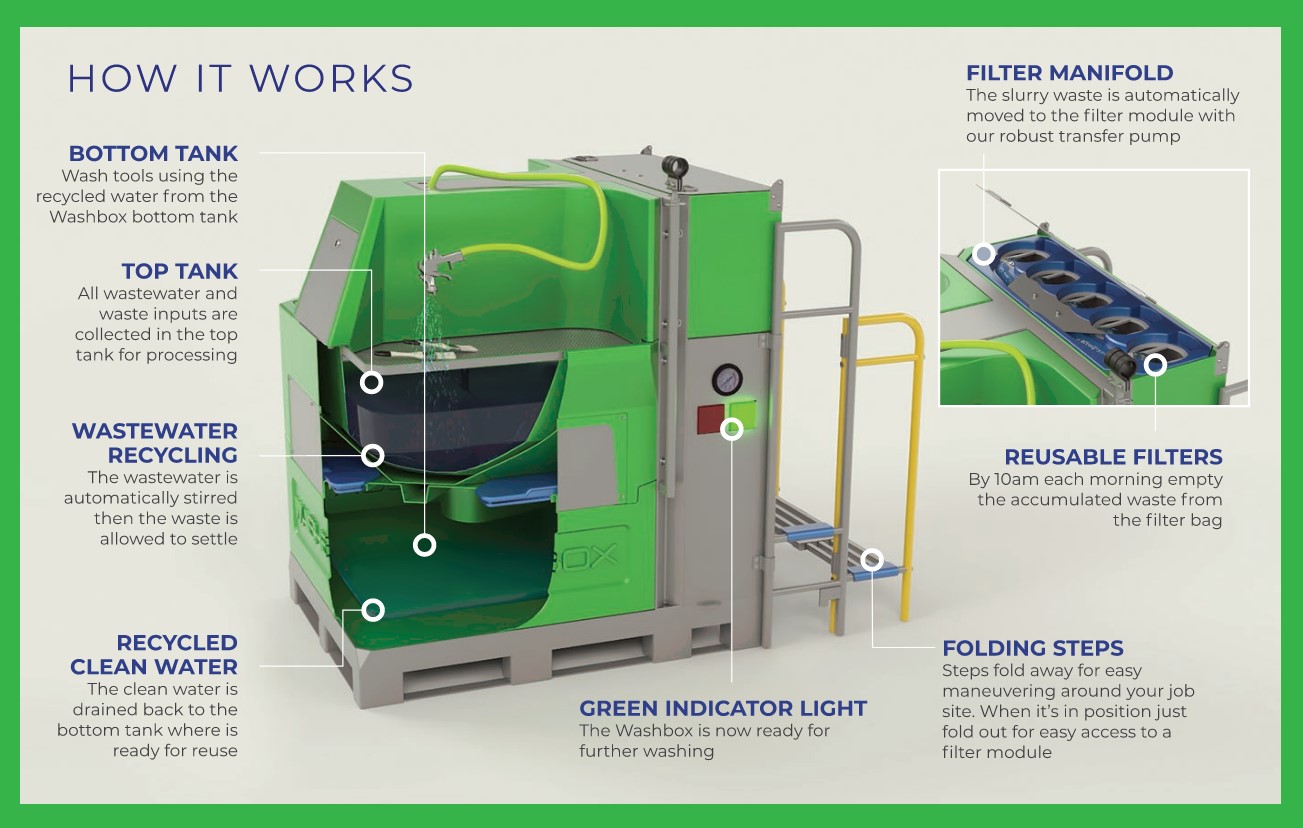

We are making significant strides in our commitment to sustainability with the introduction of the innovative Washbox equipment wash out station. This technology promises remarkable water and waste savings, as well as energy efficiency.

The Washbox station, now undergoing a trial at TQEH, features an impressive water-saving ability and a reduction of liquid waste by up to 98%.

One of the standout features of the Washbox system is that there's no need to add more water. Over a nine-month period, it can save up to a staggering 100,000 liters of water by recycling its own water from the main tank. During the initial setup, it requires just a one-time fill-up of 500 liters, making it an incredibly sustainable solution from the get-go.

There is also very little maintenance with the Washbox system. All we need to do is just empty the filters, which collect sediment.

The Washbox system is not only eco-friendly but also versatile. It's suitable for use with cement and water-based products, completely eliminating the need for solvents.

To ensure that the Washbox system is used to its full potential, an onsite training session was conducted by a Washbox representative for the relevant subcontractors who will be utilising the system.